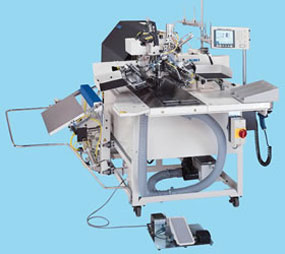

Juki APW-297

Features

- For straight pocket with flap

- Automatic Pocket Welting Machine with Automatic Welting Patch Feeder

- Newly developed devices (optional) for upgrading the basic performance of the machine

- *The same optional parts are offered for the APW-297 and APW-298. Since optional parts can't be retrofitted to the machine after purchase, be sure to specify any that you may need when placing your order.

- The knife is motor-driven

- To cut the welting patch as short as possible, it automatically adjusts itself to the sewing length established on the operation panel. This enables more consistent welting patch feed and folding operations

- The welting patch cutting knife is located under the welting patch table. This keeps the knife from damaging the garment body. In addition, the knife can be changed with ease

- Welting patch cutting, a job conventionally done by hand in the after-process, is no longer required. The result is a substantial reduction in the processing time

- The clamp exclusively used during welting patches cutting allows the cutting device to cut welting patches even when the binder is in the lower position. This further eliminates wasted time due to welting patch cutting

- Automatic flap and pocket bag feeder: SA104

- Automatic flap feeder: SA103

- Higher productivity

- The length of thread remaining after thread trimming is further reduced to eliminate thread picking

- The length of thread remaining at the beginning and end of the seam has been shortened to 15 mm for needle thread and 22 mm for bobbin thread

- Thread picking to streamline the after process is no longer required

- The shortened remaining length of thread can reduce bobbin thread waste, increase the number of welts sewn per bobbin, and reduce the frequency of bobbin thread changing

- Shortened cycle time

- When running at its maximum sewing speed of 3,000 rpm, the machine increases the traveling speed of the clamp foot and promises an extremely rapid response time at startup and stop

- This explains the machine's unrivalled production speeds among automatic welting machines

- The operator can set the next welting patch, flap (with the automatic flap feeder), and garment to be sewn while still sewing those currently set. This shortens the cycle time and increases productivity

- The machine is equipped with excellent capabilities as standard

- Needle-feed system using a stepping motor

- Newly developed division binder

- Crank-type folding plate

- Automatic welting patch feeder

- Large-size operation panel with improved capabilities

- As many as 100 different patterns can be stored in memory and 10 different cycle sewing programs can be established

- The direct drive method is adopted to drive the machine

- APW-298 for slanted pocket with flap

- Dart reference marking lamp

- Bobbin thread remaining amount detecting device

- Bobbin thread winder

- Complete with table stand and motor

|

Juki APW-297

Automatic Pocket Welting Machine

Price: $51,000.00(You can always remove it later.)

|

In addition to improved seam quality and increased productivity, the APW-297 and APW-298 also delivers dramatic improvements in basic performance such as better maintainability, reduction in thread length after thread trimming, and the adoption of a needle-feed type machine head and direct-drive machine-activating method.

|

Newly developed welting patch cutting device and automatic flap/ pocket bag feeder are now optionally available. These components work to upgrade seam quality and further increase productivity over all processes, including the after-process.

|

|