Juki FLS-350NB

Features

- This handstitching model produces stitches with a soft-to-the-touch feel

- With its increased feed efficiency, the machine feeds heavy-weight materials with greater reliability

- The wider space under the arm further enhances workability

- Commercially available synthetic thread is also applicable

- The machine is provided as standard with a thread-feeding device

- Complete with table stand and motor

|

Juki FLS-350NB

Electronic Handstitching Machine (Thick Thread)

Call For Price:

(800)544-5858

|

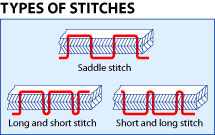

Thorough studies on stitch structure helped us design a machine that could sew softer-feeling stitches.

The machine produces consistent-quality soft-feeling stitches with just the right slack to make them look as if they're just lying over the fabric.

In addition, the regulating knob permits easy adjustment of stitch formation and provides a wider adjustment range.

|

The machine can handle a wider variety of threads. It supports not only JUKI-specified threads, but also commercially available synthetic threads that are easier to purchase.

(Please use the commercially available brands of synthetic thread designated by JUKI.)

|

By pressing the thread-feeding switch with a material placed on the machine, the machine head rotates by 150 degrees, causing the lower looper to automatically draw in a 1,200mm length of thread. This eliminates the nimble finger-work conventionally required to measure the length of synthetic thread and arrange cut-to-length pieces of thread.

|

The vertical distance provided between the underside of machine arm and the bed surface has been increased to widen the space under the arm for easier handling of sewing products.

In addition, for improved operability the machine has been ergonomically designed to provide not only a shorter distance between the operator and the needle entry area, but also a reduced foot pedal resistance for more comfortable foot control.

|

The range of vertical movement of the top feed dog and presser foot has been increased to improve the efficiency of feed and enable the feed of multi-layered sections of material. This feature helps the machine support an increased variety of heavy-weight materials for coats, etc.

|

|